Test- en measurement system up and running in no-time;

Create recipes or processes using our graphical process editor;

Safe operation with an integrated safety system;

Reduce start-up costs with the “plug and play” concept;

Completely integrated with Wizzo LIMS and Wizzo Cloud!

Introducing awesome features

Wizzo extended the abilities for test- and measurement systems with a new software framework created with National Instruments, LabVIEW. The framework “Wizzo Lab Control” is created for laboratory applications and has powerful controlling and logging capabilities.

Whether it’s an easy or complex pilot plant, any laboratory application can be set up in a short amount of time with Wizzo Lab Control.

Due to the standardized software architecture, the system can be modelled to the specifications of the (end) client, using smart configurators and proven toolkits.

Get started right away

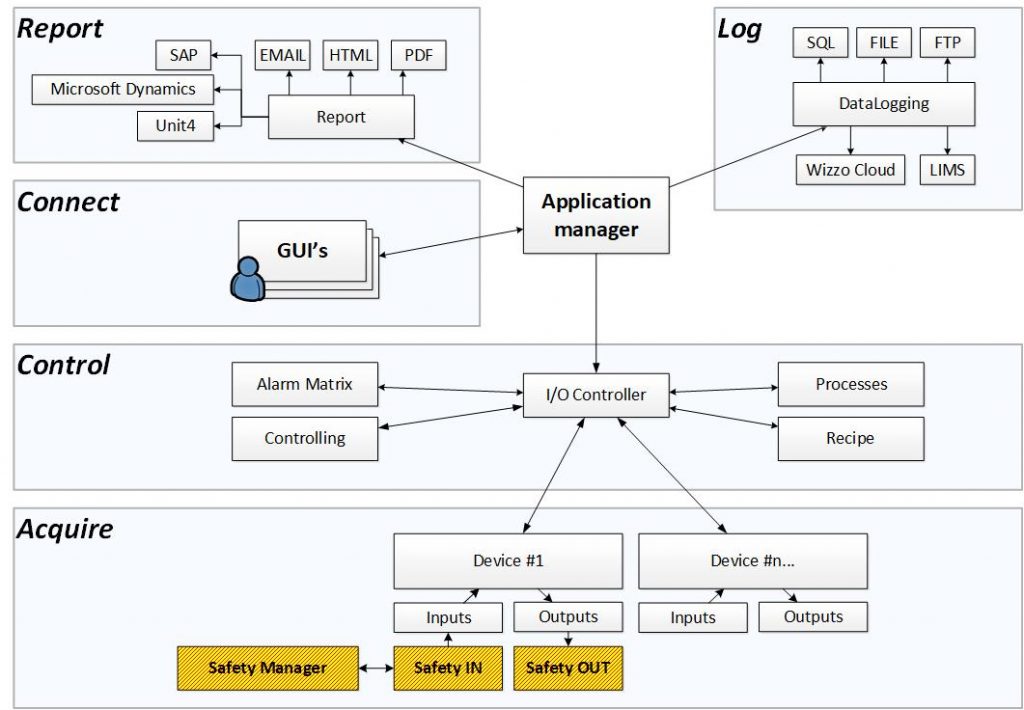

The architecture of Wizzo Lab Control is based on modules which perform their own specific tasks. A module can be an instrument- or device driver or a connector to LIMS, a SQL database or another connected system.

Wizzo has developed an extended library of modules, supporting a diversity of typically used devices and instruments. This saves a lot of time in development and debugging getting the system quickly operational.

Platform independent

Wizzo Lab Control is platform independent and supports currently Microsoft Windows, Microsoft Server, Linux en Linux Real-time. The software runs on both desktop systems as well as industrial hardware such as High Level PLC’s like National Instruments, Beckhoff and Wago.

Diversity of fast and easy functions

The software has a diversity of standard and easy to use functions which are direct accessible. This allows the user to easily configure or select the desired functionality, creating the desired functionality and user interfaces.

Sharing test results? Wizzo Lab Control is optimized for integration with Wizzo LIMS and / or Wizzo Cloud. This allows authorized users to analyze data using an encrypted connection.

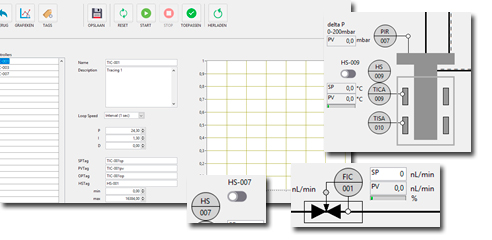

Intuitive user experience

Designing the Wizzo Lab Controls user interface, ergonomics and intuitive usage, were key. All functions on the screen are, for example, optimized for touchscreens. Other objects such as controlling buttons are located on positions on the screen that are easy to find and make sense.

This resulted in a design that needs almost no explanation or instruction, making the system a pleasure to use.

Features

Installation

- Out of the box framework

- Easy configuration

- Based on LabVIEW

- Plug and play functions and libraries

- Plug and play device drivers

- Plug and play instrument connection

- Plug and play connection to LIMS or other management systems

- Templates for custom modules and drivers

- Runs on compact RIO and other high level PLC systems

- Runs on desktop PC’s

Hardware

- Read and write to analog and digital I/O

- Integrated scaling with automatic logging of historical settings

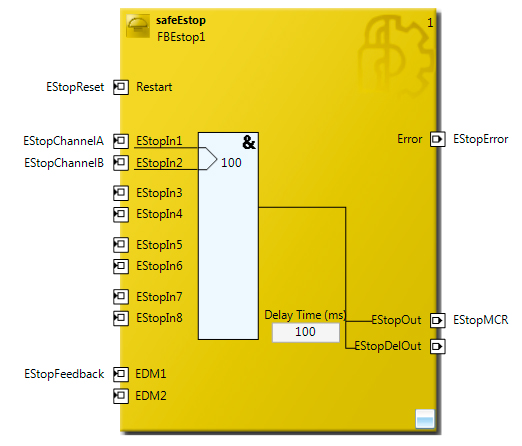

- Integrated Safety Controller

- Connect unlimited devices

- Configure safety actions using Cause & Effect matrix

- Modular hardware design. Add, remove or modify devices easily

Safety

- Integrated SIL-3 safety controller

- Analog and digital safety channels

- Configurable machine safety

- Safety extendable over multiple racks, modules, devices and channels

- Easily change alarm levels

Controllers

- Real time controllers

- Supports FPGA

- Free configurable internal and / or external PID controllers

- Extended Fuzzy, PID and Cascade PID controllers

Processes and recipes

- Easily create experiment recipes

- Create multple tasks or instructions in processes

- Create processes (recipes) with our graphical or text oriented process editor

- Run multiple processes simultaneously

- Import and export processes

- Design your experiments in a webbrowser (when integrated with Wizzo LIMS)

User interface

- Connect multiple screens (GUI’s) from multiple locations

- User friendly interface with easy and understandable interaction

- Microsoft Windows look and feel

- Actions and buttons in application ribbon

- Standardized symbols and objects for optimized Recognizability

- Extended libraries with standardized objects, controls and indicators

- Custom P&ID screens

- Easily insert process diagrams in screens

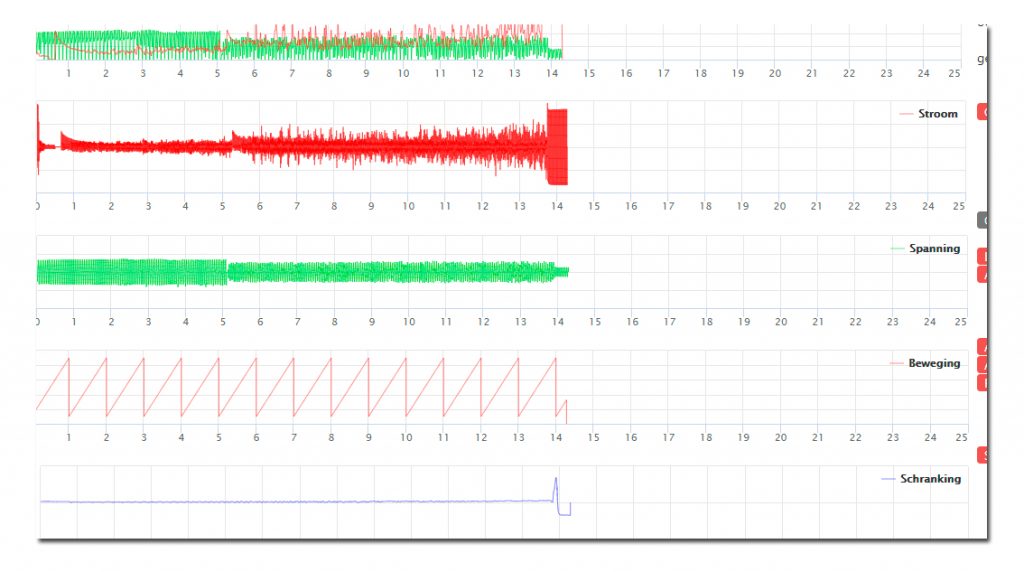

- Advanced graphs adaptable to user preferences

- Create views, signals, channels and calculations

- Optimized voor touch screen usage

- Extended graphical options for controlling, recipes and experiment evaluation

- Advanced trouble shooting

- Automatized logging of machine and user actions

- Supports multiple languages

- switch between languages based on user profile

- Extended user management

- Extendable without programming knowledge

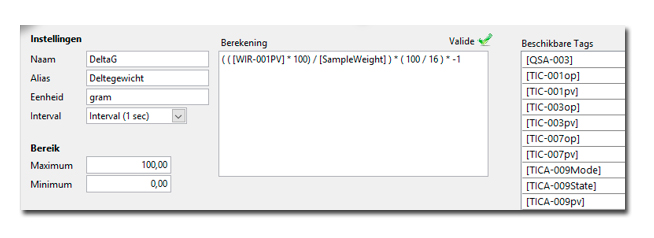

Calculations and formulas

- Create easy, real time calculations on live signals

- Apply complex formulas

- Apply calculated values in e.g. PID-controllers, logging, recipes or processes

- Use buffers for averaging and other statistical calculations

User and groups

- Extended users and groups

- Multiple user groups and rights per group

- Apply permissions to:

- Actions

- Objects on screen

- Pages

- Functions

- Experiment results

- Switch to preferred language on user login

- Log in with smartcard and / or user name / password

Logging

- Log results to LIMS, databases, data files or directly integrated into Wizzo LIMS or Wizzo Cloud

- Automated logging of:

- User actions

- Application events

- Alarms

- Application or machine actions

- External alarms

- Process steps or recipe events

- Automated conversion and handling of (big)data types like:

- (Alpha) numeric data

- Waveforms

- Files

- Images

- Video’s

- Sounds and vibrations

- Export application logs for integrity tests and validation

Report

- A variety of default templates

- Create custom reports

- Send status e-mails periodically or on triggers

- Publish results or reports to websites

- Evaluate experiment results in a webbrowser

- Integrate directly into Wizzo Cloud

Motion

- Complete motion integration

- Control multiple axes (also from recipe or process)

- Interpolate up to 8 axes

- Easily integrate motion movements in research experiments

- User friendly tuning

- Communication with external controllers integrated

Vision

- Complete vision integration

- Combine machine vision data from a variety of systems

- Powerful modification and calculation on images and streams

- Realtime calculations in recipes and processes

- Optimized for logging of images and video streams

Tests

- Extended debug facilities

- Test pilot plant software without hardware using device simulation

- Conduct full experiments in FAT-mode simulating the complete process

- Fast switching between test, development or live environment

Special features

Custom functions can easily be integrated into the framework. Our skilled and experienced software engineers can modify the software to comply with the customers wishes. The module based architecture allows us to apply and test modifications in a short amount of time.

The framework is scalable creating an easy to maintain platform increasing the joy of maintenance and extends the lifetime of the software.

Supported instrument and device drivers

- National Instruments cRIO, cDAQ, FPGA;

- Beckhoff CXxx platform;

- Ethercat devices;

- CAN devices;

- OPC DA & UA devices;

- Modbus TCP/IP, Modbus Serial;

- Metrohm Dosimat;

- Fluke digital multimeters;

- Brooks instruments Mass flow Controllers;

- Eurotherm 2400, 3500 series controllers;

- Galil DMC-series motion controllers;

- Nabertherm furnaces;

- NMEA devices;

- Emerson controllers;

- Endress Hauser instruments;

- Agilent GC’s en Mass spectrometers;

- Mettler Toledo scales;

- JUMO controllers;

- Telemecanique TWIDO PLC’s, Frequentieregelaars;

- Datalogic scanners;

- Micromeritics;

- Julabo thermostaten, warmtebaden;

- Bentrup controllers;

- Siemens S7 PLC;

- Promag RFID readers;

- SPI, I2C devices;

- Wago PLC’s en controllers;

- Bronkhorst flowbus;

- ISCO pumps;

- JASCO pumps;

- Arduino microcontrollers;

- Valco valves;

- Bischoff pumps;

- ABB VIP protocol devices;

- Allen Bradley PLC’s;

- IKA stirrer;

- Intel based GPIO;

- Zebra barcode printers;

- Jenny Science controllers;

- Dymo label printers;

- Pyroscience, Firesting O2.