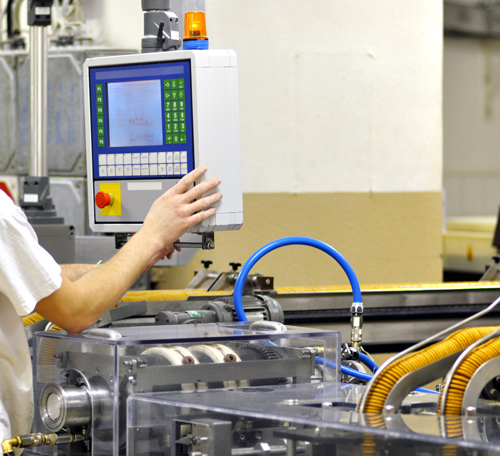

Cooperating with an experienced machine builder, Wizzo has developed a Motion Control application for control of multiple axis systems to perform advanced movements. This software is used in CNC or CAM (Computer Aided Manufacturing) designs and machines.

With the flexibility, math capacity and extended possibilities of LabVIEW, the HMI (Human Machine Interface) is capable of performing the most complex coordinated functions and movements. This allows the application to handle high speed movements and anticipate quickly on process values.

Proxmotion

The application, named Proxmotion, is developed in cooperation with Novako Techniek and is used in a variety of industrial production solutions. The software is used for controlling plasma cutters, press and punch systems, laser cutters or a combination of these systems.

Novako Techniek is specialized in mechanical engineering and creating production systems. Having a background in Operations and working with systems for production purposes, their engineers have full insight in the requirements of the end product.

Proxmotion's software framework is flexible and can control a large number of axis and I/O. These ingredients essential for the development of mission critical systems.

Coordinating moves

Flexibility and speed are key in controlling high speed production systems. Our software can communicate with various motion systems including, but not limited to, Galil, Schneider Electrics, ABB, Omron, Siemens and GE Fanuc.

Wizzo has developed algorithms that allows faster communication and increased stability.

CAD CAM

Turning designs into products is one of the advantages of Proxmotion. Using the onboard CAD CAM solution, Proxmotion can easily convert a CAD drawing into a program of coordinated moves. Being tuned to the production system, the CAD CAM system advises in optimal and material efficient manufacturing.

More information?

Wizzo IT Solutions

De Trompet 2222

1967DC Heemskerk

The Netherlands